Series LMBV Lateral Reducing Ball Valves

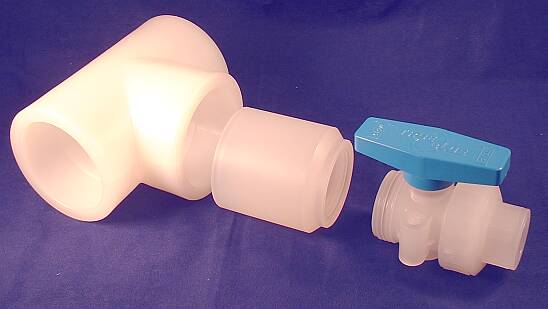

in PVC, CPVC, PVDF & Natural Polypro • With Piping Tee

Simplifies Lateral Connections • Improves Piping Safety

• Replaces “Zero Dead-leg” Valves*

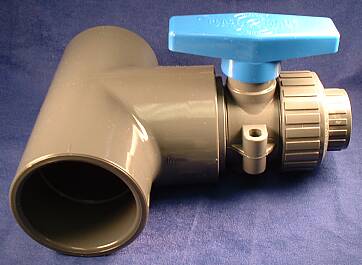

Plast-O-Matic Trunnion Ball Valves are available with an adapter and tee for substantially stronger and more compact valve connections to lateral piping. This design eliminates the need for a reducer, additional length of pipe, and one of the end connections on the ball valve. Advantages over traditional ball valve tee connections:- Faster plumbing — reduces labor.

- The overall length is shorter; valve body is partly inside the plumbing tee.

- Design enables removal of valve and access to internals.

- Resists piping stresses better than traditional “reducer” connections.

- Eliminates potential variations in pipefitting.

- Assembly is substantially stronger than pipe + reducer + fittings.

Use in place of zero dead-leg valves:- Lower cost.

- Virgin, non-pigmented Kynar PVDF and Natural Polypro compatible with all butt fusion piping systems.

- Zero-static area* similar in size to diaphragm valve; uses same concept of turbulence/flushing action to prevent deadleg.

- Valve is threaded into adapter — a true union — easier maintenance, easier changes in piping system.

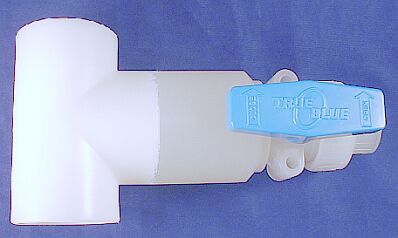

Note in the photo at right, the smooth, tapered transition the adapter provides from the tee to the ball valve. The outer diameter meets ASTM specs for socket fusion, and the end is suitable for butt fusion. Note also that the distance from the union to the closed valve is well within the standard "six pipe diameters" that defines dead leg. * Important note concerning Zero Dead-Leg: Not all size and material combinations provide compact dimensions. Please consult factory.

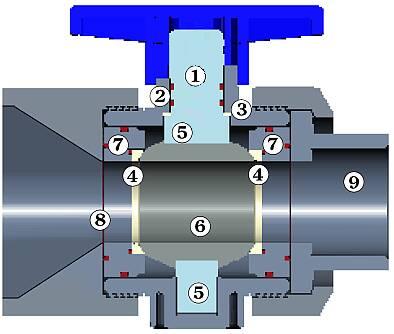

Design Advantages:- Reinforced shaft eliminates stem breaks.

- Double shaft O-rings.

- PTFE shaft bearing eliminates friction and wear.

- PTFE seats backed up with O-rings reduce the wear and tear of repeated cycling.

- Trunnion Design: Upper and lower supports retain ball under pressure. Trunnion design allows multi-directional flow; means that the valve is in no danger of being installed "backwards."

- Concentric machined and mirror-polished ball.

- Dual sliding seats use triple O-rings for balance and maximum leak protection.

- LMBV Connection provides compact connection and is welded or heat-fused conveniently to tee in main; eliminates reducing bushing, pipe connection and union end — yet still permits access to valve internals.

- True union end for ease of piping lateral drops from valve.

Additional Features:- Molded mounting brackets for excellent support and ease of piping installation.

- Pressure rated at 175 PSI (11,91 BAR). Kynar® PVDF ball valve rated to 232 PSI.

- 100 percent pressure tested production.

- Available in Geon® PVC, Corzan® CPVC, Natural (virgin, unpigmented) Polypropylene, and Kynar® PVDF. Available seal materials are EPDM and FKM. Other materials available; minimum quantities apply.

- Available with NPT threaded connections, sockets, flanges, metric, or BSP.

- Three-way ball valves available in PVC and CPVC.

- Vented Ball Valves available for sodium hypochlorite.

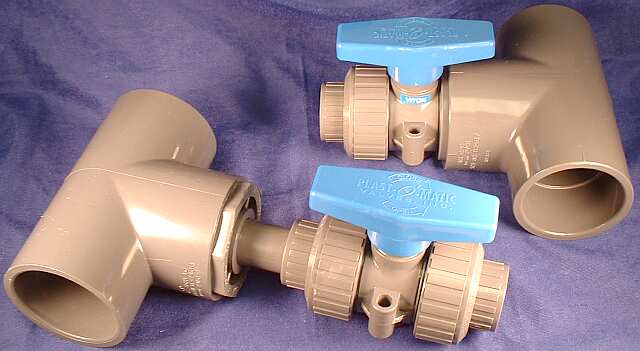

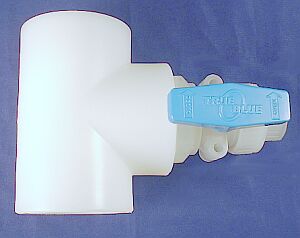

Compare the LMBV with traditional ball valve connections: Note the compact LMBV, shown at rear in the photo above. The ball valve is an integral part of the tee. A traditional lateral drop, shown in the foreground, uses a reducing bushing and a section of pipe. Not only is this more time consuming, it has a significant weak spot between the bushing and the valve, takes up a lot more space, and is seldom dimensionally identical from installation to installation. Each Adapter fits spigot and socket connectors: Note the two photos below. Each patent-pending adapter meets O.D. specifications for socket connectors; the same adapter meets O.D. and I.D. specifications for butt fusion connectors. No need for different type connectors. Socket Fusion | BCF Fusion |  |  |

Specifications:

CAD Drawing:For dimensional drawings in CAD .DWG format, please click here and refer to prefix LMBV. Ordering Information:

Tee included; size must be specified with order.

|